Insulating silicone rubber – Experience superior protection

Hefeng is a leading provider of high-quality liquid silicone rubber and insulating silicone rubber solutions, trusted across industries such as electronics, automotive, medical, and consumer goods.

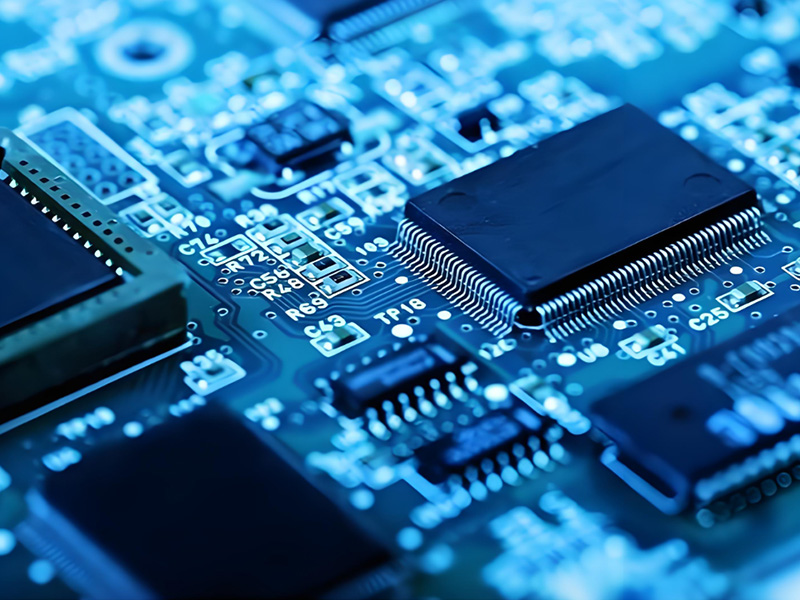

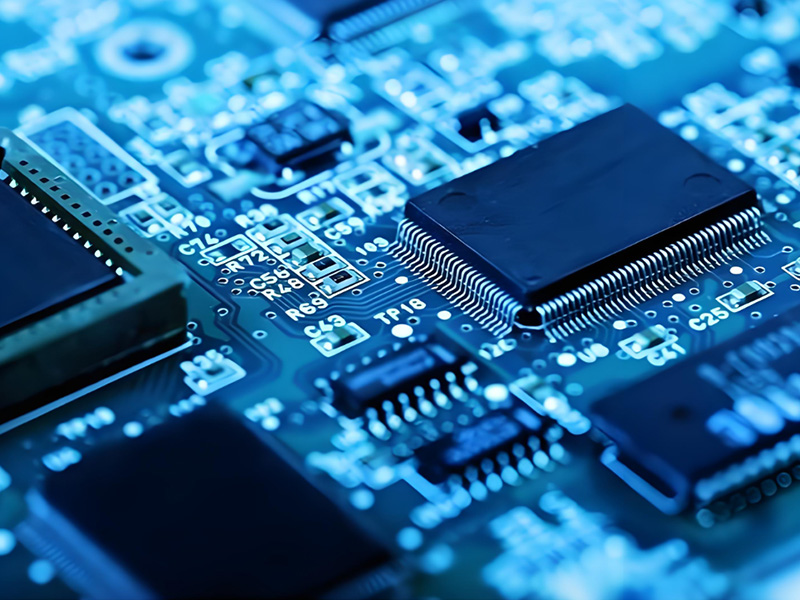

In today’s fast-paced industrial landscape, the demand for materials that deliver exceptional flexibility, thermal stability, biocompatibility, and electrical insulation has never been higher. At Hefeng, we specialize in premium silicone rubber materials engineered to meet the highest standards of performance, reliability, and safety. Our liquid silicone rubber is ideal for applications ranging from medical devices, babyware, and food-grade products to precision mold making, thanks to its outstanding durability, chemical resistance, and aging stability. Meanwhile, our insulating silicone rubber offers superior electrical resistance and thermal insulation, ensuring optimal protection for sensitive components in electronics and automotive systems. Whether you're seeking long-term durability, regulatory compliance, or advanced material performance, Hefeng delivers silicone solutions that support innovation and manufacturing excellence.

Product Center

Insulating Silicone Rubber Advantages

● Superior Electrical Insulation

Insulating silicone rubber boasts high electrical resistance, with a volume resistivity of 10¹³–10¹⁵ Ω·cm, ensuring minimal current leakage. It can withstand high voltages (15–30 kV/mm), making it ideal for power transmission and electronic components.

● Exceptional Thermal Stability

Unlike many organic rubbers, Insulating silicone rubber remains stable across a wide temperature range, from –60°C to +250°C. This ensures that it maintains its insulating properties even in high-heat environments like motors, transformers, and aerospace applications.

● Weather and Chemical Resistance

Insulating silicone rubber resists UV radiation, ozone, and oxidation, extending its lifespan in outdoor conditions. It is also impervious to moisture and many chemicals, making it suitable for industrial and marine environments.

● Flexibility and Mechanical Durability

Its elasticity allows Insulating silicone rubber to absorb shocks, making it ideal for applications like cable insulation, seals, gaskets, and electronic encapsulation. It protects sensitive components from vibrations and electrical leakage.

● Hydrophobic Properties

The material is naturally water-repellent, which prevents moisture-related issues like electrical failures and degradation, especially in polluted or humid environments.

Liquid Silicone Rubber Advantages

● Biocompatibility

LSR is hypoallergenic, resistant to bacteria, and safe for medical applications like skin-contact products.

● Durability and Resistance

It performs well in extreme temperatures (-60°C to 180°C) and is resistant to chemicals, UV light, and oxidation, making it perfect for automotive and outdoor use.

● Mechanical Strength

LSR has high tensile strength, tear resistance, and flexibility, ensuring reliability in seals and parts subjected to physical stress.

● Versatility

With its ability to be easily pigmented and molded into intricate shapes, LSR is used in a variety of applications, from medical devices to consumer products.

● Fast Production Cycle

The efficient molding process reduces production time and costs, enabling high-volume manufacturing.

LSR combines durability, versatility, and speed, making it a top choice across industries.

Application

Industrial & Instrument

Insulating silicone rubber is essential in industrial instrumentation, offering excellent sealing, insulation, and shock absorption for applications like seals, buttons, and thermal management in harsh environments.

Aerospace And Automotive Parts

Insulating silicone rubber is used in aerospace and automotive industries for seals, shock absorbers, insulation, and damping, offering high temperature resistance, durability, and safety in extreme conditions.

Power Transmission

Insulating silicone rubber is ideal for power transmission applications due to its high electrical resistance, thermal stability, and ability to withstand extreme temperatures and harsh environmental conditions.

Medical Device

Silicone rubber is widely used in medical devices due to its biocompatibility, flexibility, chemical stability, and durability, making it ideal for applications like catheters, prosthetics, and surgical tools.

Industrial & Instrument

Silicone rubber is essential in industrial instrumentation, offering excellent sealing, insulation, and shock absorption for applications like seals, buttons, and thermal management in harsh environments.

Food Processing

Silicone rubber is widely used in food processing for applications like baking molds, cooking tools, packaging, and baby products due to its temperature resistance, antibacterial properties, and safety.

Frequently Asked Questions (FAQs)

Q1: What makes Insulating silicone rubber a preferred choice for insulation?

Q2: Is Insulating silicone rubber resistant to environmental factors?

Q3: What are the advantages of Insulating silicone rubber over traditional materials?

Q4: What is Liquid Silicone Rubber (LSR)?

Q5: What are the key applications of LSR?

Q6: What are the benefits of LSR?

Related Blogs

-

Hefeng Silicone company is located in Wenzhou, China, It has more than 200 employees on staff and a building area of approximately 20,000 square meters. All of our products have passed ISO9001/ISO14000/ISO45001 certifications. Our products have also passed FDA, LFGB, RoHS, MSDS, and UL certifications,etc. We have obtained numerous patents for our research and development results. We have also received numerous certifications from authoritative departments. Company Honors: Awarded the titles of "National High-tech Enterprise," "County Star Enterprise," "High-growth Industrial Enterprise," "Wenzhou City Enterprise Technology R&D Center," and "Annual Top 100 Enterprises in Yongjia County" for several consecutive years. It has also been awarded the title of "Specialized and Innovative Enterprise" and has established a "Zhejiang University-affiliated Research and Development Base" in collaboration with a well-known university.

Hefeng Silicone company is located in Wenzhou, China, It has more than 200 employees on staff and a building area of approximately 20,000 square meters. All of our products have passed ISO9001/ISO14000/ISO45001 certifications. Our products have also passed FDA, LFGB, RoHS, MSDS, and UL certifications,etc. We have obtained numerous patents for our research and development results. We have also received numerous certifications from authoritative departments. Company Honors: Awarded the titles of "National High-tech Enterprise," "County Star Enterprise," "High-growth Industrial Enterprise," "Wenzhou City Enterprise Technology R&D Center," and "Annual Top 100 Enterprises in Yongjia County" for several consecutive years. It has also been awarded the title of "Specialized and Innovative Enterprise" and has established a "Zhejiang University-affiliated Research and Development Base" in collaboration with a well-known university. -

Hefeng Silicone Group A.15 years of development history, with three branches, a total scale of 20,000 square meters, and a benchmark enterprise in the Made-in-China industry, B. Raw materials are first-hand supplied, with more than 40 stable suppliers, and the lowest price among peers, C. Fully automated advanced machine production, passed ISO9001/ISO14000/lso45001 certification. All products have passed; FDA, LFGB, ROHS, MSDS, UL and other certifications, D. Professional R&D team of more than 10 people, including solid engineers and liquid engineers, and 15 precision experimental instruments and equipment, E. Accept sample customization and drawing customization, as long as the customer needs, we can make samples and produce.

Hefeng Silicone Group A.15 years of development history, with three branches, a total scale of 20,000 square meters, and a benchmark enterprise in the Made-in-China industry, B. Raw materials are first-hand supplied, with more than 40 stable suppliers, and the lowest price among peers, C. Fully automated advanced machine production, passed ISO9001/ISO14000/lso45001 certification. All products have passed; FDA, LFGB, ROHS, MSDS, UL and other certifications, D. Professional R&D team of more than 10 people, including solid engineers and liquid engineers, and 15 precision experimental instruments and equipment, E. Accept sample customization and drawing customization, as long as the customer needs, we can make samples and produce. -

Hefeng Silicone was established in 2010 and is a high-tech enterprise committed to the research, production, and sales of special silicone rubber products, such as compounding silicone rubber, power insulation silicone rubber, flame-retardant silicone rubber, fumed silicone rubber, food-grade silico

Hefeng Silicone was established in 2010 and is a high-tech enterprise committed to the research, production, and sales of special silicone rubber products, such as compounding silicone rubber, power insulation silicone rubber, flame-retardant silicone rubber, fumed silicone rubber, food-grade silico

Related Videos

Keep in touch with us

Mob:+86-13566239436

Wechat: +86-13566239436

E-mail:hefengsilicone2024@126.com

Address:

No.449, Industrial Ring Road, Dongmeng Industrial Zone, Wuniu Street, Yongjia County, Wenzhou China.