Views: 182 Author: Site Editor Publish Time: 2025-09-10 Origin: Site

Power insulation silicone rubber has become one of the most discussed materials in the field of electrical and thermal engineering. The growing demand for reliability, durability, and safety in modern industries has accelerated the adoption of this versatile compound. But what exactly makes this material stand out? Unlike traditional insulators, silicone rubber used in power insulation combines flexibility with high resistance to heat, cold, and environmental stress. This adaptability ensures that it performs consistently in high-voltage environments, extreme climates, and demanding industrial applications. To fully understand its role, we need to look deeper into its structure, advantages, and wide range of uses.

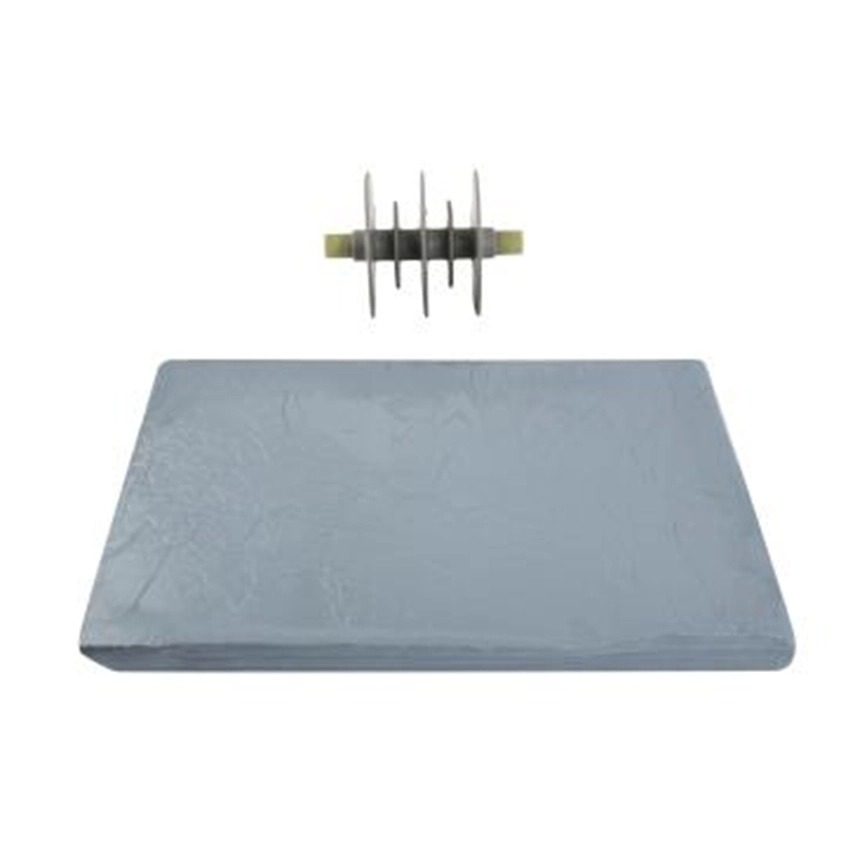

At its core, power insulation silicone rubber is a synthetic elastomer formulated from silicone polymers with additional fillers to enhance dielectric strength. Its molecular structure allows it to maintain flexibility while resisting electrical conductivity, which is the key to its insulating capability. When used in electrical systems, it acts as a barrier between conductive parts, preventing short circuits, power leaks, and dangerous arcs. Beyond electrical resistance, silicone rubber also displays excellent hydrophobic properties. This means that even in wet or humid environments, it resists moisture absorption and maintains its insulating power.

One of the most compelling aspects of this material is its thermal stability. Conventional insulators may crack, melt, or lose elasticity under prolonged heat exposure, but silicone rubber withstands high temperatures without degradation. Conversely, in freezing conditions, it remains pliable rather than becoming brittle. This temperature resilience ensures uninterrupted performance in industries such as power transmission, automotive, aerospace, and renewable energy. To put it simply, power insulation silicone rubber works by combining electrical safety with environmental endurance—two qualities rarely found in a single material.

The superiority of power insulation silicone rubber can be seen when comparing it to conventional insulating materials such as plastics, ceramics, or thermoset polymers. While these traditional materials have been widely used, they often fall short in terms of flexibility, weather resistance, and long-term reliability. Plastics, for instance, may deform or release harmful gases when exposed to heat, while ceramics—although excellent at resisting electricity—are rigid, brittle, and prone to breakage.

Silicone rubber, however, provides a balance that others cannot achieve. Its elasticity allows it to absorb mechanical stress without cracking, making it ideal for environments where equipment vibrates or shifts. Its weather resistance ensures that exposure to ultraviolet light, ozone, or salt does not lead to surface erosion. Furthermore, unlike many insulators that degrade over time, silicone rubber maintains its dielectric properties for extended service life, reducing maintenance costs. In short, it bridges the gap between electrical performance and environmental resilience, a critical combination for industries pushing toward greater efficiency and reliability.

Power insulation silicone rubber has found applications across a wide spectrum of industries due to its reliability and adaptability. In the electrical power sector, it is used extensively in high-voltage insulators, cable terminations, and surge arresters. Its ability to handle fluctuating voltages without losing performance makes it a cornerstone in maintaining stable power grids. In transportation, particularly electric vehicles and rail systems, silicone rubber ensures that components remain insulated despite high temperatures, vibrations, and exposure to outdoor conditions.

In aerospace, the material’s lightweight nature combined with superior thermal resistance plays a vital role in protecting sensitive wiring and electronic systems. Renewable energy systems, such as wind turbines and solar power stations, also rely on silicone rubber for insulation, as these installations must withstand constant exposure to harsh outdoor climates. Even in consumer electronics, silicone rubber insulators provide compact, safe solutions where miniaturization demands high efficiency in small spaces. Clearly, the scope of its application goes beyond just insulation—it represents an enabling material that makes modern innovations possible.

A defining feature of power insulation silicone rubber is its performance stability in extreme conditions. Traditional insulators often face performance drops when exposed to sudden environmental stress, but silicone rubber’s structure resists rapid deterioration. For example, in desert regions where daytime heat soars and nighttime temperatures drop drastically, silicone rubber remains consistent in its properties. Similarly, in polar conditions, it avoids brittleness that could otherwise lead to fractures in electrical systems.

Additionally, silicone rubber’s resistance to ultraviolet radiation ensures that long-term outdoor exposure does not result in surface cracking or chalking, which could compromise insulation. Its chemical stability also protects it against corrosive environments, such as coastal areas with salty air or industrial zones with pollutants. This resilience makes it particularly valuable in global infrastructure projects where diverse climates must be considered. Engineers often choose silicone rubber because it minimizes the risk of sudden failures, ensuring uninterrupted service in mission-critical applications.

To better understand the practical benefits of power insulation silicone rubber, the following table summarizes its core advantages compared with other insulation materials:

| Feature | Power Insulation Silicone Rubber | Conventional Insulators |

|---|---|---|

| Temperature Resistance | -60°C to +250°C | Limited range |

| Flexibility & Elasticity | High, even in extreme cold | Often brittle |

| Electrical Insulation Strength | Excellent | Varies by type |

| Weather & UV Resistance | Outstanding | Often poor |

| Lifespan & Durability | Long-term stability | Shorter life cycle |

| Maintenance Requirements | Low | Frequent replacements |

From this comparison, it is evident that silicone rubber outperforms conventional options in almost every category. It delivers not only technical superiority but also long-term cost savings, as the reduced need for replacements and maintenance lowers the total cost of ownership. Furthermore, its ability to provide safety in high-risk environments ensures compliance with modern safety standards, which is another reason industries increasingly rely on it.

Q1: Is power insulation silicone rubber environmentally friendly?

Yes, while its production requires specialized processes, its long lifespan reduces waste from frequent replacements, making it a more sustainable choice in the long run.

Q2: Can it be used in household applications?

Absolutely. Although it is primarily found in industrial and large-scale systems, silicone rubber is also used in home electronics, small appliances, and safety equipment.

Q3: Does it require special installation procedures?

While basic installation is similar to other insulators, its flexibility allows easier handling and shaping, which simplifies the process compared to rigid alternatives.

Q4: How does it compare in cost with traditional insulators?

Its initial cost may be slightly higher, but the extended service life and reduced maintenance make it more economical overall.

Q5: Can power insulation silicone rubber withstand fire hazards?

Yes. Many formulations are flame-retardant, meaning they can self-extinguish or resist burning, providing additional safety in high-voltage environments.

In today’s fast-paced technological landscape, industries cannot afford interruptions caused by unreliable insulation materials. Power insulation silicone rubber provides a solution that meets modern performance standards while anticipating future demands. Its adaptability across sectors—from power transmission to electric vehicles—shows that it is not limited to one niche but instead acts as a universal enabler of progress. The combination of safety, efficiency, and cost-effectiveness makes it a long-term investment rather than a short-term expense.

Moreover, as industries move toward greener and more sustainable practices, the durability of silicone rubber reduces resource waste and environmental impact. Its ability to operate in extreme conditions ensures that future infrastructure, even in remote or harsh environments, can remain resilient. By choosing power insulation silicone rubber, industries align themselves with both safety and sustainability goals. In essence, it is not merely a material—it is a strategic choice for building the future of reliable power systems.